With today’s pipelines more likely to be carrying dirty gas, significant measurement errors are becoming increasingly common because the cause of the error is imperceptible by many traditional flow measurement technologies. If not detected quickly, even a small amount of liquid or other contamination in the bottom of a pipe can significantly increase Lost And Unaccounted For (LAUF) product and financial risk.

Improve Fiscal Metering Confidence

Rosemount Dual-Configuration 3410 Series Gas Ultrasonic Meters detect process upsets and changing flow dynamics before they affect measurement accuracy. Featuring two meters and transmitters in a single body, these new meters offer unique path layouts that enable greater visibility into gas quality and device health, as well as continuous on-line verification of custody transfer measurement integrity. Two sets of electronics with a patented, synchronized transducer firing technique further enhances meter performance by ensuring lightning fast sampling for real-time detection of flow disturbances. This two-in-one redundant design improves fiscal metering confidence while ensuring regulatory compliance by permitting two completely independent measurements with the installation of just one flow meter.

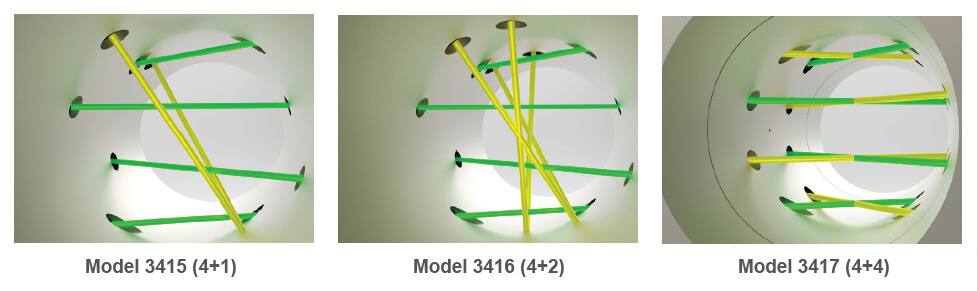

The primary meter in each model is a field-proven Rosemount four-path, chordal, British Gas design meter, certified to the most stringent OIML R137 1&2 Accuracy Class 0.5. The secondary meter varies by model, offering either reflective path technology or a second set of four chordal paths.

Rosemount Model 3415 (4+1) and 3416 (4+2) Gas Ultrasonic Meters combine a four-path fiscal meter with an added check meter, while the 3417 (four-path plus four-path) meter provides two fiscal meters for full redundancy and equal accuracy in one meter body.

These meters provide additional measurement confidence by calculating corrected volume rates, mass and energy rates and real-time AGA 10 speed of sound. This ensures a repeatable and accurate flow measurement, even when process conditions vary or differ from calibrated conditions.

Get Advanced Insight

Figure 1. Path Layouts of Rosemount Dual-Configuration (click to enlarge image)

- Model 3415 for Integrated Check Metering

Achieve measurement verification with this 4+1 meter featuring a 4-path chordal design and a single reflective path at a 30⁰ angle that ensures early warning of process changes. This meter is ideal for transmission pipelines and industrial interconnects. Click here to learn more. - Model 3416 for Advanced, Integrated Check Metering

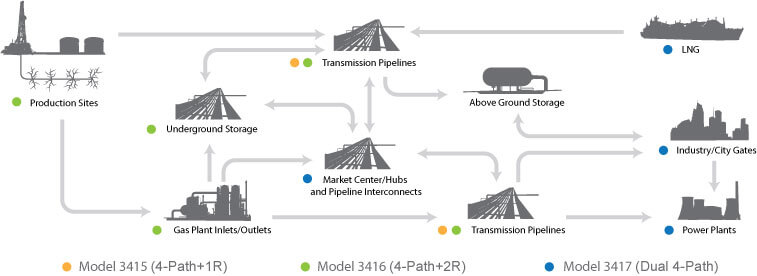

Detect trace amounts of liquid or debris along the bottom of the pipe with this 4+2 meter that offers an additional reflective path at a 90⁰ angle – this extra diagnostic path helps pinpoint the cause of a shift. The 3416 is ideal for production and gathering applications, underground storage, gas plant inlets/outlets, and transmission pipelines. Click here to learn more. - Model 3417 for Fully-Redundant Metering

Validate measurement and maximize uptime with this 4+4 meter that features two completely independent, four-path meters in one body for the ultimate in reliability. This design significantly reduces cost for measurement stations that traditionally utilize two separate meters with their associated piping, calibrations and installations. The 3417 is ideal for border stations that are becoming bi-directional, storage applications, remote locations such as offshore platforms or for use on large compressor stations or lines without a bypass. Click here to learn more.

Figure 2. Typical Application Sites for Rosemount Dual-Configuration (click to enlarge image)

Meet Operational Demands with the Combined Chordal and Reflective Path Design

The packaging of direct path measurement and reflective path technology combined in one ultrasonic flow meter body, as is the case in the 3415 and 3416 meters, helps avoid common mode error as chordal and reflective paths react differently to process changes. The reflection technology sees even small amounts of liquid or contamination on the pipe wall that remain completely hidden in a direct path design. This is particularly important when metering rich, dirty or wet gas. Additional benefits of reflective path technology include:

- Giving operators advanced warning of adverse flow conditions, process upsets and/or meter deviations by offering improved sensitivity to pipe wall changes

- Minimizing measurement errors with real-time detection of liquid volume fractions (LVF) of as little as 0.1% inside the pipe

- Ability to trigger an alarm at 1.0% deviation (or user defined limit) within the flow computer or SCADA system

Extend Calibration Cycles

Trending data from two independent transmitters help extend calibration cycles, enabling maintenance to be condition-based instead of calendar-based. With built-in diagnostics, operators can easily track meter performance to baseline to help streamline maintenance and reduce inspection in the field for significant cost savings. Embedded expert knowledge help less experienced technicians interpret diagnostics to resolve problems more rapidly. Maintenance is no longer prescriptive, but condition based.